-

-

-

Total payment:

-

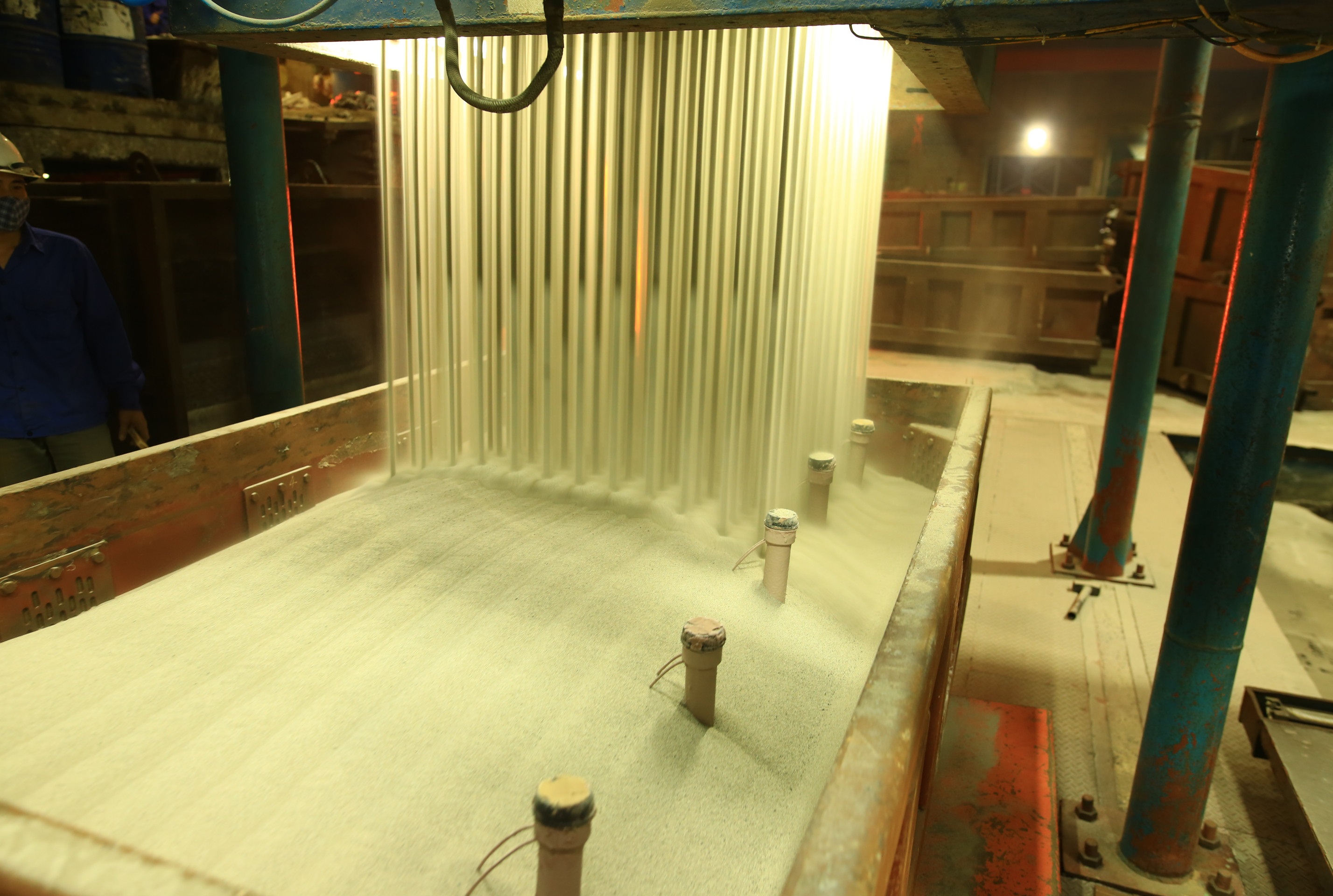

Lost-foam Casting Line

Posted by Vico Casting at 17/11/2021

Lost-foam casting technology is the leading modern and advanced casting technology in Vietnam today with many outstanding advantages compared to traditional methods.

Lost-foam casting technology: is a modern technology and newer than traditional technology.

Stages as below:

1. Preparation stage:

a. Mold-making step:

– Cut styrofoam to make molds

– Attach the foam mold to the feeder

– Paint the mold with a layer of special paint (anti-collapse when sand is inserted, high temperature resistant)

– Dry the paint layer

b. Steel melting step:

– Mix steel materials with other additives to put into the furnace

2. Casting stage:

– Put the mold in the sandbox

– Pour the melted ingredients into the mold through the mold funnels

– Vacuum to make the mold firm

– Wait for the product to freeze

– Remove the product from the sand tank to cool and clean (by a blower to clean the surface paint on the product)

3. Heat-treatment stage:

– Transfer the product into the furnace after finishing casting.

4. Machining and completing stage:

– Detach the product from the feeder

– Grind, polish products or machine, turn details

– Stock the finished product.

5. Testing stage:

– Products during the melting stage are sampled and tested to determine the mechanical properties of the product, and analyze the grain texture inside the product (by modern spectrophotometer).

Advantages of Lost-foam Casting Technology: High-accuracy castings significantly reduce the need for additional machining after the casting stage, reduce environmental pollution, and reduce the costs of material consumed when making molds.