-

-

-

Total payment:

-

Vacuum Casting System

Posted by Vico Casting Export Company Limited at 30/12/2019

The most advanced and modern casting technology in Vietnam today is vacuum casting, which has numerous advantages over traditional methods.

Vacuum casting technology: a modern and newer technology than traditional methods.

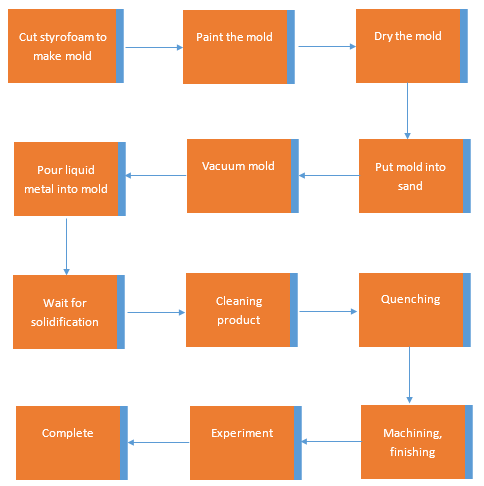

Steps:

1. Preparation

a. Pattern Making

– Cut styrofoam to make the mold

– Attach the foam mold to the beans

– Paint the mold with a layer of special paint (anti-collapse when sand is inserted, heat resistant)

– Dry the paint layer

b. Metallurgy

– Mix steel materials with additives and load them into the furnace

2. Molding

– Put the mold in the sandbox

– Pour the melted ingredients into the mold through mold funnels

– Vacuum to make the mold firm

– Wait for solidification

– Remove the product from the sandbox to cool and clean (with a shot blasting machine to clean the surface paint on the product)

Vacuum Casting Process

3. Quenching

– The product is moved to a heat treatment furnace after casting

4. Machining, finishing

– Remove the product from the mold

– Grind, polish products or processing, turning

– Put in warehouse

5. Experiment

– Products are tested during production to determine the mechanical properties of the product and analyze the grain texture inside the product (by a modern spectrometer).

Advantages of vacuum casting technology: High-precision casting greatly reduces the need for additional processing after the casting process, reduces pollution, and reduces the cost of consuming raw materials when making molds.